PVC Geomembrane

ATS Synthetic (Pvt.) Ltd. » Products » Geomembrane » PVC Geomembrane

High-Performance PVC Geomembrane Liners for Water Containment

ATS Synthetic’s PVC geomembrane liners provide an essential impermeable barrier for projects requiring long-lasting containment of liquids and vapors. Designed to meet industrial standards, our geomembranes are ideal for applications such as water conservation, civil engineering, and hazardous waste management. These flexible, durable liners adapt easily to various installation sites, from dams and reservoirs to tunnels and basements.

As Pakistan’s pioneer in PVC geomembrane production, ATS Synthetic offers industrial-grade PVC geomembrane solutions that adhere to the PVC Geomembrane Institute (PGI) specifications. Our state-of-the-art manufacturing process ensures durability, flexibility, and ease of installation in even the most challenging conditions.

Advantages of PVC Geomembrane

- Easy to install: It is an elastic material that can conform readily to irregular shapes and differential settlement.

- Excellent mechanical properties

- High degree of flexibility

- Excellent elongation percentage and reduced expansion coefficient

- Puncture resistance

- Impact resistance

- Good tear and tensile strength

- Cost-effective & long useful life: Minimizes water losses, reduces maintenance costs, and increases the life of structures.

- Good endurance properties

- Resistance to biological degradation

- Resistance to chemical degradation

- Good thermal behavior (hot or cold)

- Superior frictional characteristics

- Acceptable uniaxial extinction and excellent biaxial flexibility

Applications of PVC Geomembrane

Water Conservation

- As a liner to prevent reservoir and dam water loss

- Artificial lake lining

- Fish pond lining

- Agricultural ponds

- Decorative ponds

- Drainage lining

- Canal lining

- Agriculture reserve water storage

- Irrigation ditch

- Firewater holding ponds

- Raw water reservoirs and lakes

- Industrial/agricultural reserve water storage

- Golf course water holes and sand bunkers

Civil & Architectural Engineering

- As a liner to control seepage in tunnels

- Water drainage

- Embankment protection liner

- Shoreline protection against sea water corrosion or sinking of the ground

- Road base and pit

- Earth Seepage Control

- As a waterproofing liner in basements

- As a waterproofing liner in walls

- As a waterproofing liner in roofs

- Oil Drilling Reserve Pits

- Concrete Basement

- Water Proofing Liners

Environment

- As a liner Waste liquids i.e. sewage slugs

- As a liner for radioactive and hazardous waste management

- Waste conveyance canals

- Solid waste landfills /garbage dumping sites

- Waste Treatment Pond

- Covers for power plant coal ash

Industrial

- Industrial water/liquid storage tanks

- Solar concentration pond

- Salt field drying bed

- Chemical / Brine Solution Collection System Liner

- Pulp and Paper Landfill & Swage Ponds

- Handling and transportation of liquids

Seaming Methods

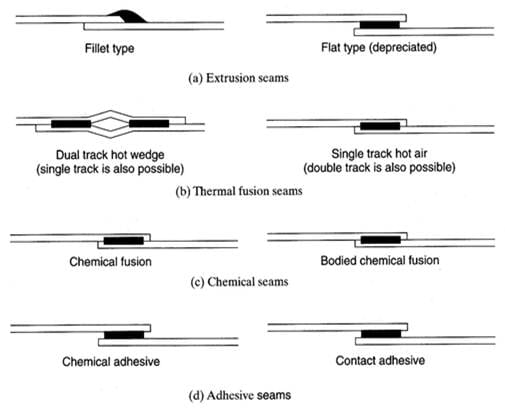

The methods of seaming geomembranes are shown schematically in the accompanying figure.

ATS geomembrane is available from 0.25 mm (10 mil) to 2.00 mm (80 mil) thickness, with a width of up to 90 inches. To meet the installation efficiency requested by customers, the product softness can be appropriately adjusted. If you don’t see a product that suits your needs on our site, talk to our technical expert staff, and we will assist you with your plan.

Frequently Asked Questions (FAQs)

What is a PVC Geomembrane, and where is it commonly used?

A PVC geomembrane is a flexible, polymer-based liner used to prevent fluid or vapor leakage in various projects. It’s commonly used in water reservoirs, waste management, tunnels, and industrial storage tanks.

How is PVC Geomembrane different from HDPE Geomembrane?

While PVC geomembranes are highly flexible and adaptable to complex surfaces, HDPE geomembranes offer greater puncture resistance and chemical stability, making each suitable for different environmental conditions and project needs.

What thickness of PVC Geomembrane is best for water conservation projects?

For water conservation projects, thicknesses between 0.5mm and 1.5mm are often ideal, providing durability while still allowing flexibility for easy installation.

How does ATS Synthetic ensure the quality of its PVC Geomembranes?

ATS Synthetic adheres to PGI (PVC Geomembrane Institute) specifications and uses advanced calendaring technology to produce high-performance PVC geomembranes. Rigorous quality control ensures durability, flexibility, and environmental resistance.

What methods are used to seam PVC Geomembranes on-site?

Common methods for seaming include hot air welding, hot wedge welding, and solvent welding, which create a strong, impermeable seam that ensures continuous containment.

Is ATS Synthetic's PVC Geomembrane suitable for harsh weather conditions?

Yes, our PVC geomembranes offer excellent resistance to UV rays, chemical exposure and extreme temperatures, making them reliable in harsh environmental conditions.

Can ATS Synthetic's PVC Geomembranes be customized to specific project needs?

Absolutely. We provide PVC geomembranes in various thicknesses and softness levels for enhanced installation flexibility. Contact our technical experts for custom sizing and recommendations for your unique project.

We are always ready to help you and answer your questions